How I studied? Hard and a lot. Blog post over.

Read MoreGrowth in 2017: New hires for all trades at DesignTech

Since the start of the year, we have been adding depth to the roster! In the first half of the year, our Leesburg, Virginia office added additional staff in the electrical and plumbing engineering departments. Ken Poulter and Jhonny Suarez Diaz have added a great amount of experience and training to the company as well as a great culture of excellence in their work.

Ken has over 30 years of experience in the plumbing engineering field; including over 20 years as a studio director and/or plumbing department head. In addition to design expertise of sanitary, water, natural gas, and medical/compressed air systems, his experience has provided him with extensive multi-disciplinary exposure and building code knowledge. He serves with DesignTech as a plumbing designer, project manager, quality control resource, and business development team member. His responsibilities also include development of project specifications and construction administration.

Jhonny has fourteen years of experience in the Electrical Engineering field as both a master electrician and electrical engineer. His experience has provided him extensive knowledge of the National Electrical Code, electrical installations and maintenance, and project troubleshooting. In addition, he has specific experience with development and implementation of method of procedure (MOP) protocols, and assessment of mission-critical infrastructure systems for safeguarding data center uptime. His skills also include assessment of energy consumption for periodic efficiency figures (PUE) as well as whole project data. His responsibilities at DesignTech include building site visits, investigative reports, project engineering, construction administration, development of specifications, cost estimates, and lighting calculations.

Most recently, Ross Lynam has joined our Kensington, MD office as a mechanical engineer. Ross graduated this year from Penn. State University with a Bachelor of Science in Mechanical Engineering. Ross has already worked on several projects in both the private and public sector and is poised to become a more independent project engineer with each project he has under his belt.

Read more about Ross, Jhonny, and Ken by clicking on their photos below!

AIA Continuing Education: DesignTech now offering accredited courses!

For the last few years, DesignTech has been providing architects with informal continuing education topics including Variable Refrigeration Flow (VRF), HVAC 101, and a guide to DCRA Energy Verification Sheets. In an effort to further reward our AIA member attendees, we are pleased to announce that as of early this year, DesignTech has become an official American Institute of Architects Continuing Education System (AIA CES) Provider! We are now approved to develop curriculum and present face-to-face in Maryland, Virginia, and Washington, DC!

Thus far, the focus of what we can offer has been on our experience and solutions to common challenges faced by architectural/engineering teams. Specifically, we have developed our first course, offering "20 Products to get you out of a Bind”. This presentation is designated as a part of the health, safety, and wellness category (HSW) of continuing education; which in this case means a high focus on the deliverable to the client. The most common of these design challenges include:

- Spatial constraints

- Aesthetic functionality

- Code requirements

- Budgetary restrictions

- Acoustic requirements

- Thermal comfort

- A/E team coordination

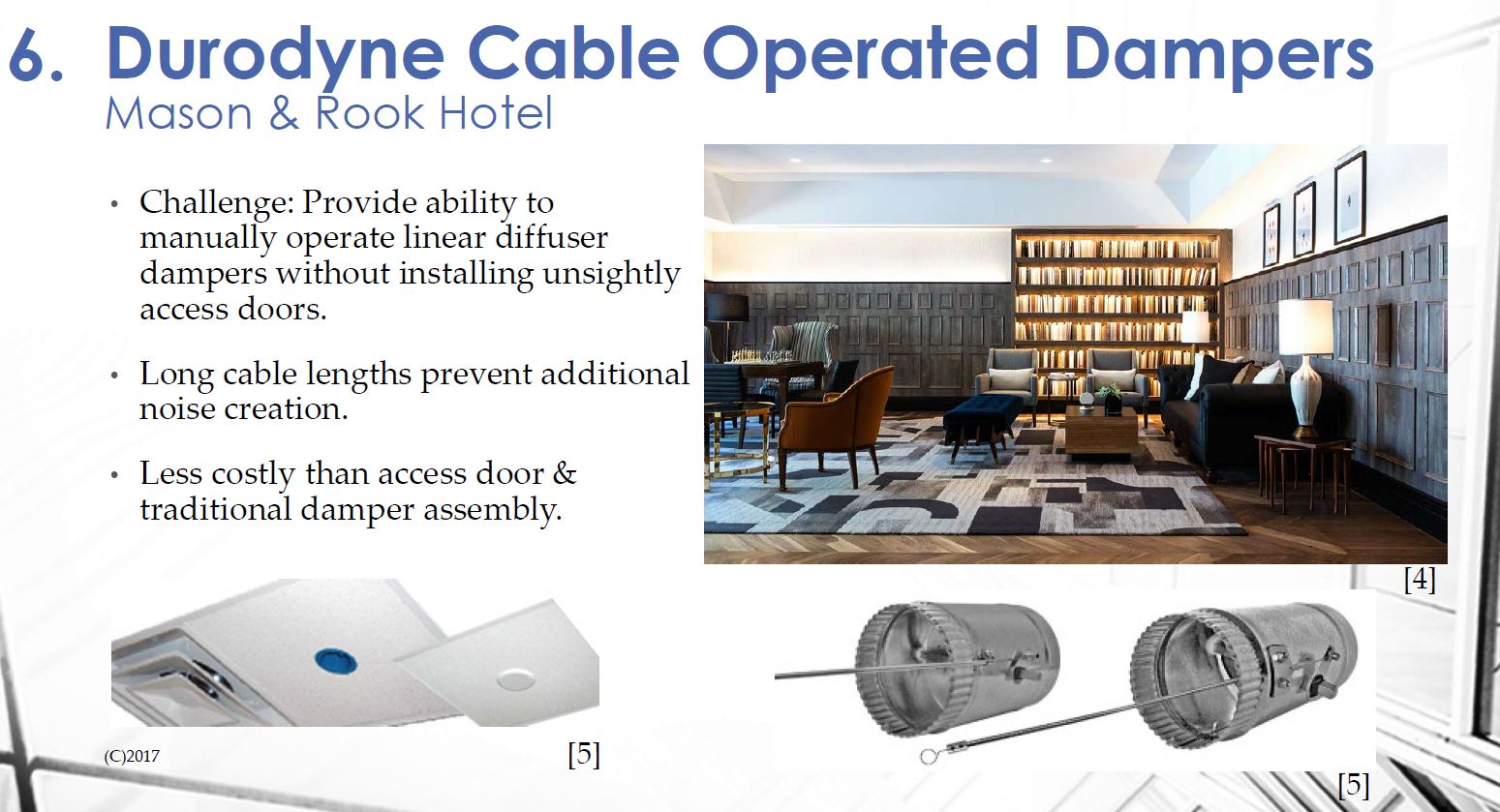

One product in the presentation is a cable operated manual volume damper. This product, specified by the mechanical engineer, provides the ability for proper air balancing at air devices installed in gypsum board ceilings without a need for a costly/unattractive access door. Below is an excerpt from our presentation:

In presenting each of the other 19 challenges, we explain how the standard Mechanical/Electrical/Plumbing design products could fail to achieve the desired performance standard. We also detail how the solution product addresses each of these shortfalls. Finally, we provide a case study from work that DesignTech has completed where the product was used.

We have been fortunate to present this to six architecture firms over lunch and are still interested in sharing this information with more people! If you are interested in this presentation, and would like us to come over to your office, please reach out to us! You can contact our business development manager Kim Dize through email at kdize@designtecheng.com to schedule a date! We are looking forward to hearing from you!

Help us continue to make the built world better!

AHR Expo 2017: 4 Things We Learned

The AHR Expo can be overwhelming, that should be number one on the list. Three days with more than 68,000 engineers in front of thousands exhibitors, I think that's the definition of a nerd fest. Before I get too far, I was fortunate enough to go to the Expo because Havtech, one of our local product reps, was taking a group of its clients. I owe a special thanks to them for the incredible learning experience. During my time in sunny Las Vegas, I attended five different seminars, a number of manufacturer's hospitality events, and walked the showcase floor for a few hours. I was able to see new product releases, hear from market trend experts, and learn all kinds of solutions that can help me design better HVAC/R systems. The following are the four biggest takeaways from the Expo:

1. VRF is here to stay. Global trends show that Variable Refrigerant Flow (VRF) equipment is the largest growing sector of the equipment HVAC market and is projected to grow another 10% next year compared to a market average of 2% growth in the USA. We have shared in this trend with many of our retrofit projects in 2016 utilizing VRF. The VRF equipment as well as most mini-split systems utilize inverter compressor technology. This inverter technology is required by legislation in Europe though it is only in about 10% of compressors in the USA. Trend experts expect this be brought into the USA energy codes in the coming years. The only hindrance to VRF and mini-splits is changes in international trade partnerships which eliminate the competitiveness of the Asian manufacturer's products (LG, Mitsubishi, Samsung). Currently Daikin is the only manufacturer here in North America producing VRF equipment.

2. Closed loop water quality is a critical part of any retrofit (especially boilers). We see a number of projects each year where old cast iron boilers are being replaced with stainless steel condensing boilers that boast incredible efficiencies. If the new boilers are introduced to hydronic loops with debris and scale, the precision boilers can be ruined in as little as months. Likewise, if a new boiler is installed in a water/glycol loop that isn't properly flushed, cleaned, and filled the warranty is often voided.

3. Product highlight: EnOcean Alliance. EnOcean Alliance is a group of companies that are developing self-powered, wireless, control devices for everything from lights to humidity. Their series of products allows for the elimination of batteries, cabling, and control compatibility issues while now allowing things like light switches to be placed on glass, easy connection with building automation systems, and flexible room configuration. It's an awesome series of products https://www.enocean-alliance.org/en/home/

4. Occupant Comfort is King. The most common thread through each seminar was a focus on ensuring building occupants are comfortable. Comfort doesn't just mean having a thermostat in every room. Both new products and seminars focused on radiated energy flow and humidity (renamed by one presenter as building hydration) as additional key elements to maintaining high indoor environmental quality (IEQ). High IEQ helps landlords renew lease agreements, and helps occupants be more productive. In the case of hospitals, a lack of proper building hydration is now clearly linked to a rise in airborne bacteria and virus spread. Simply put, small water particle size, resulting from low humidity, allows for viruses and bacteria to remain in the circulated airflow for up to 48 hours. Even in less critical environments, count on occupant comfort being a category of design which is more closely paid attention to.

- Evan Bjorndal, Mechanical Engineer

NAIOP Northern VA: And the Winners Are...

Earlier this month, DesignTech attended the NAIOP awards gala for the Northern Virginia chapter! Principals Tom Igo and Matt Bowers attended on behalf of DesignTech at the Ritz Carlton in Tysons Corner, VA. Though MEP engineering consultants are not recognized as winners, many DesignTech clients, both architects and contractors, are often winners. Last year, Architecture Incorporated won the award of excellence for their interiors retail design of the Tower Club; a project in which DesignTech provided MEP services. This year there were three Designtech 2016 clients who won awards! Though they were not on DesignTech projects, we are thrilled to congratulate Form Architects, Architecture Incorporated, and Collective Architecture for their wins! We are privileged to work with design firms who do such excellent work!

Pictured below is Matt and Tom at the event with the Balfour Beatty team in attendance .

Sparta, Wisconsin: Modular Chiller Witness Test

This past Tuesday, DesignTech participated in the witness test and demonstration of the modular chillers for an undisclosed interiors project in Washington, DC. DesignTech served as the owner's representative; verifying that the system met the design specifications. The test took place in Sparta, Wisconsin at the Multistack chiller manufacturing facility.

The manufacturer demonstrated the proper operation and startup of the eleven chiller modules and two end suction chilled water pumps. The Multistack facility in-house tests their equipment with a hydronic system capable of testing three of the 30-ton modules at once. The performance testing was completed successfully; with each module proving the nameplate data to be accurate. The chillers were specified with complete factory controls that were complete at the time of the testing. The completion of the controls installation allowed the factory to demonstrate the sequences of normal operation as well as a myriad of failure condition responses including but not limited to:

- Power source out of phase

- Circuit failure(s)

- High head pressure condition at compressor

- Loss of flow to module

- Loss of leaving chilled water temperature sensor input (fail to run sequence)

- Loss of pump drive control

- Primary chilled water pump failure

Multistack did an excellent job in their demonstration and their product line is a testament to their willingness to customize equipment for specialized applications. Stay tuned for to see this modular chiller at work once it is shipped to Washington, D.C.

On-the-job Experience: 2016 DesignTech Interns

Joining the DesignTech team this summer are two engineering interns! Chad Callahan is working from the Kensington, MD office while Christopher Liu is in the Leesburg, VA office. Both interns declined to comment for the blog post, stating that they were having too much fun doing engineering to take a break. Both Chad and Chris are pursuing engineering undergraduate degrees; Chad for mechanical and Chris for electrical. Chad will begin his senior year at the University of Maryland, College park in the fall while Chris returns to the University of Virginia for his sophomore year. Both Chris and Chad have already contributed in AutoCAD drafting, lighting load and density calculations, product specifications, and field survey. DesignTech is always looking for great new interns. If you are interested or know someone interested in an internship during any part of the year, please reach out to us at info@designtecheng.com

Christopher Liu - Leesburg, VA Intern

Chad Callahan - Kensington, MD Intern

Rendering vs. Reality: The Grilled Oyster Company

Renderings have changed significantly over the last 5 years. The widespread use of BIM (building information modeling) software has made renderings more accessible, and accurate to the vision of building owners. These changes are improvements in every sense.

Anyone with a Revit license now has the ability to create renderings, and walkthroughs, without killing time working on two software platforms or double modelling building elements. Additionally, the level of detail in renderings has grown exponentially. Modeling real fixtures, and finishes with coordinated MEP disciplines grounds vision and opens communication for technical and non-technical team members. The rendering can also act as a benchmark for project teams for coordination and commissioning.

Just completed a month ago, project in NW Washington serves as a great testament to this accountability. Take a look below at how the rendering compares to the finished product for this 4,000 sq. ft. restaurant. The rendering was developed by Architecture, Incorporated during the project.

You can read more about The Grilled Oyster Company project here. Restaurants don't create multiple locations in the same city for no reason. The food at the Grilled Oyster Company is amazing and certainly worth a visit.